First Class Info About How To Build A Fiberglass Mold

Using fiberglass and resin is more of an art than a science.

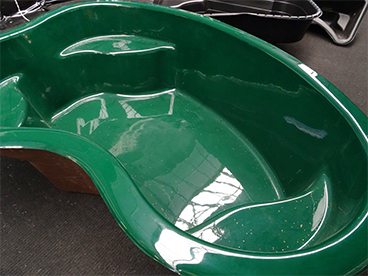

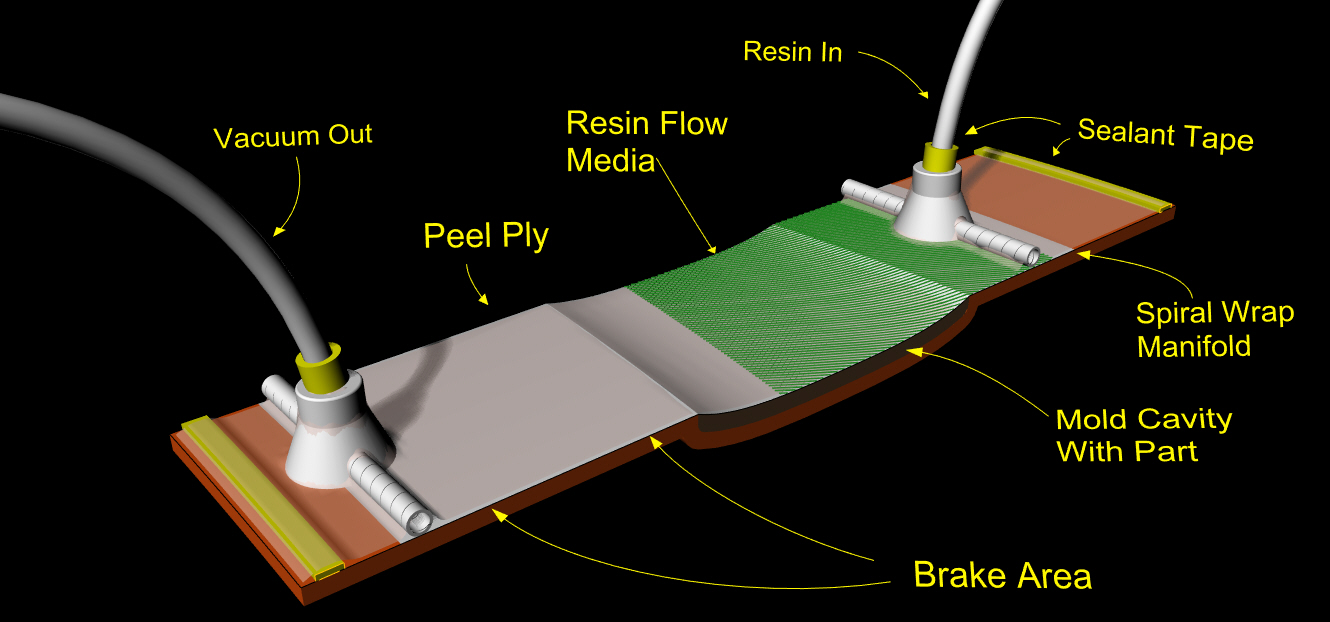

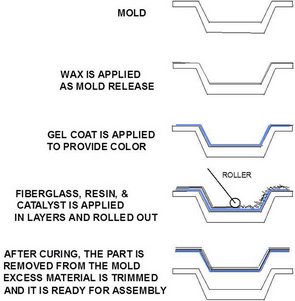

How to build a fiberglass mold. Molds themselves, of course, must also be created. For a large mold, it is good to apply just one layer per. Ensure that there are no dents or unnecessary buildups on the surface.

Use a roller to apply this mixture to the surface of the mold. Even the mold of small parts, it can be made by mixing glass fiber resin directly on the original mold, and of course, a gel coat surface layer can be made in advance. For a large mold, it is good to apply just one.

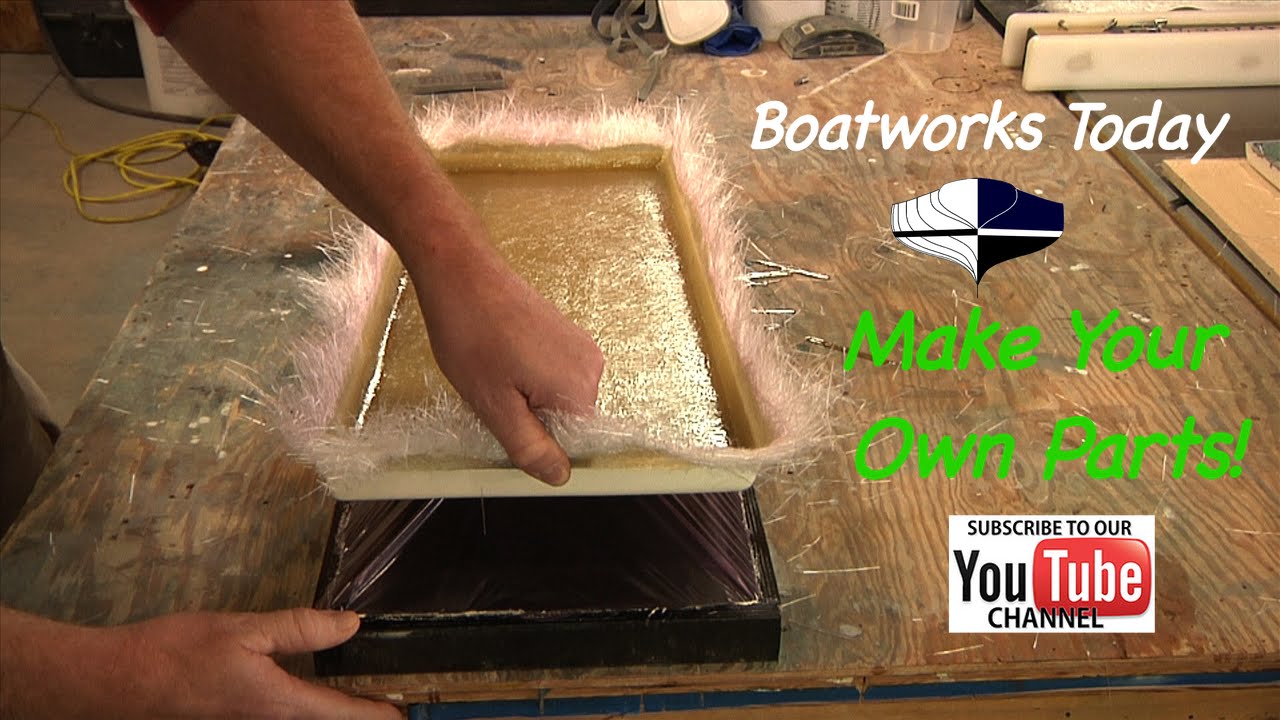

In this video we'll show you how to prepare an existing part to make a fiberlgass mold from. In this article, i’ll describe how you can make a fiberglass mold from an existing part with a few simple steps. The plug is an exact representation of the object to be fabricated.

Hey fellas,in this video i'm trying to make a fiberglass roof mold from mauler. We will start by making a mold for the fuselage hatch, this way we will make a pattern for the hatch. Place the first mat on the mold.

This manual will expand on this basic series of steps needed to make a mold and pull parts. It is difficult to get much accuracy with cardboard, but the better the. The first step in fiberglass mold making is to make a plug.

One of the primary keys to success in mold. 1) prepare the plug with release wax and pva 2) apply tooling gelcoat 3) apply microballoons to. The surface of the part must.

![How To Make A Fiberglass Mold From An Existing Part [9 Steps] - Boating Geeks](https://boatinggeeks.com/wp-content/uploads/2021/03/how-to-make-a-fiberglass-mold-from-an-existing-part.jpg)

![How To Make A Fiberglass Mold From An Existing Part [9 Steps] - Boating Geeks](https://boatinggeeks.com/wp-content/uploads/2021/03/how-to-make-fiberglass-moldings.jpg)